Previously, Toolcraft used different software systems for individual process steps, which led to a sometimes lengthy and uncontrollable data and production process. In order to optimize the metal laser melting process from design to production and post-processing, the medium-sized family business has now opted for the NX software package from Siemens.

The Cooperation

Siemens and Toolcraft signed a cooperation agreement to further advance the industrialization of additive manufacturing. Toolcraft covers the entire process chain from design, manufacturing and machining “refinement” to quality inspection and non-destructive testing according to NADCAP standard in-house. This is why Toolcraft chose the software not only for 3D metal printing, but also for NX and NX CAM for engineering and AV/NC programming.

The NX Software

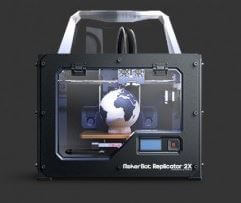

NX from Siemens PLM Software is an integrated software suite for product development and part manufacturing. It supports the fast and efficient production of high-quality products with integrated CAD, CAE and CAM modules. NX offers solutions for product development, 3D modeling and documentation, multidisciplinary calculations of structural, moving, thermal, fluid and multi-physical applications as well as complete parts manufacturing solutions for tool making, machining and quality control. The software can be easily integrated into Teamcenter® software, the most frequently used digital lifecycle management software worldwide.

From Design and Simulation to Production

The Siemens NX software offers a continuous process from design to simulation to production and machining. Feedback loops are built in between the individual process steps. The unlimited design freedom for innovative and complex parts is guaranteed. Special functions for topology optimization and the construction of grid structures are of particular interest in additive manufacturing and are therefore also integrated in NX. By checking the design guidelines of a component, NX ensures feasibility in advance. It checks wall thicknesses, any necessary support structures in certain areas and the possibility of the final removal of any powder residues in internal cavities. Thus the production success can be secured by analysis tools and simulation of the construction process. Once the design is complete, NX can be used to set up the construction panel, generate the support structures and program instructions for metal powder bed printers such as those used at Toolcraft. After printing using the laser melting process, NX supports finishing with traditional CAM instructions for machining equipment.

Source: Toolcraft

The Advantages

Urban August, Senior Vice President and Managing Director, Germany:

“Our diverse customer projects, but also neutral studies, clearly demonstrate that additive manufacturing processes and Industry 4.0 have high synergy potential in their implementation. Continuous digitization of product development speeds up the use of additive manufacturing processes considerably, as 3D printing can be performed directly from fully described digital product models. At the same time, our customers can take up the megatrend to more product variants and individualized products in small and individual series and successfully implement it.

Source: Toolcraft, Siemens NX